Load Cell

A load cell (also known as weight sensor or force sensor) is a conversion device used to convert a weight/mass signal or a force signal into an electrical signal. Now the most common type of load cell is strain gauge load cell. The strain gauge load cells are mainly used in various electronic scales, material testing machines, industrial process control, online weighing control, safety overload alarms and other fields. For example, tension load cell is used for crane scale and tension force measurement. Compression load cell is used for truck scale, platform scale, belt weigher and other weighing measurement. While tension and compression load cell is used for both weighing and force measurement.

About Us

Everyday there are a lot of topics on load cells, because load cells are everywhere. Nowadays there are so many types of load cells in the market. When you are choosing load cells, there are many points to consider. Such as the application of the weighing system, the accuracy of the load cell, the accuracy of the weighing system, the capacity of the load cell, the data signal transmission method of the load cell, etc. Here, ATO Industrial Automation are very glad to exchange experiences of load cells and provide various load cell products for you.

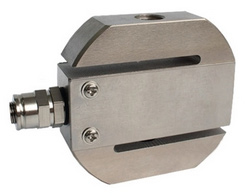

S type load cell is a tension and compression load cell. There are two thread holes just in both ends of strain gauge load cell for mounting.

S type load cell is widely used for hopper scale and mechanical scale automation renovation. S type load cell has customizable capacity from 5kg, 30kg, 100kg, 500kg, 1000kg, 2 ton to 7 ton.

S type load cell features: - Simple and compact structure, small size and light weight

- Strong anti-eccentricity and lateral load capacity

- Good Inherent linearity

- Overload protection

The normal stress annular elastic components are mostly the integrated circular structure with the upper and lower double-screw bolts or the integrated annular structure. Under compression load, the elastic annulus and the assembled structure made up of additional pressure head and base wad are usually adopted. It is a tension and compression load cell with capacity from 100kg to 20 ton. If there are special requirements on electronic hook scale, the rectangular annular elements can also be adopted. In order to improve the processing manufacturability, the internal annulus of the rectangular ring can be connected by three connecting holes, including one large central hole and two side holes. The upper and lower loading part of the rectangular elastic elements can be double-screw bolts or pulling ears connected by hinge pins.

Within the strain area of ideal normal stress and shearing stress elements, the strain degree should form a strict linear relationship with the externally-imposed load, which is also at the core of designing all load cell elastic elements. Difficulties to finish this process are mainly caused by limitations of structural design, computing and economic budget. Only when the load cell R&D and production rules and elastic element structural design and boundary selection principles are adhered to can the above limitations be resolved and the comprehensive influence of various factors be overcome to turn out the load cell with the minimum fluctuation.

Strain gauge load cell is made up of elastic elements (external load elastomer), strain resistance transformer elements (resistance strain gauge of different types) and inverters (Wheatstone bridge circuits). Among them, advancement and reasonability of elastic elements is the linchpin to high accuracy and stability of strain gauge load cells.

Taking the variable belt scale as an example whose full suspension scale rack is supported by four beam load cells, the belt scale divides four load cells into four independent signals which then enter the digital transmitter on site, the digital transmitter converts weighing analog signal into digital signal and convey it to the weighing instrument. By grouping the four independent weighing signals respectively and combining the signal of speed load cell, the weighing instrument would calculate the cumulative and instantaneous flow of three groups of feeding medium, namely one group of main cumulative flow and two groups of auxiliary cumulative flow.

A load cell is a conversion device used to convert a weight/mass signal or a force signal into an electrical signal. The strain gauge load cell is based on the strain effect. Under the action of external force, the resistance strain gauge pasted to the surface of the elastomer is deformed together with the elastomer. After the strain gauge is deformed, the resistance value changes, and the measuring circuit will convert the changes into an electrical signal and output, which indirectly measures the external force. It can be seen that the strain gauge load cell is mainly composed of three parts, namely an elastomer, a resistance strain gauge and a measuring circuit.

A load cell is actually a device that converts a mass signal into a measurable electrical signal. The working principle is to convert the weight of the object added to the scale pan into an electrical signal proportional to the weight, amplify and A/D convert the output electrical signal, and then to display the weighing information by other relevant circuit.

In recent years, weighing cheating occurs in the measurement of electronic weighbridge in many areas. Driven by economic interests, some outlaws take various cheating ways in weighing the gross weight and tare of vehicles, which may lead to a measurement deviation of several hundred kilograms to several tons, thus benefiting from it. This paper mainly analyzes the cheating ways of electronic weighbridge, puts forward the methods of on-site inspection and suggests how to prevent and avoid cheating.

The tubing belt has attracted wide attention for its environmental protection, moisture-proof and high efficiency. At present, there is a new technology that directly conveys the clinker lime powder to the steel plant in a sealed way by tubing belt, it successfully breaks the traditional dynamic measurement method of electronic belt scale, but uses two weighing hoppers to weigh in turn statically, thus achieving the goal of continuous, fast and accurate measurement.

The railway department has traceability requirements for the eccentric load display controllers of container overload and eccentric load detection devices. It calibrates the eccentric load display controllers of container overload and eccentric load detection devices

in the company according to the main methods mentioned in this article, and then measure to confirm the calibration results. Based on the calibration results, containers whose eccentric load conforms to the requirements could be loaded. After the detection and confirmation from railway freight car overload and eccentric load detecting device, over-tolerance of eccentric load data is effectively reduced.

The calibration method mentioned in this article is operated with 20 GP container, M12-grade nominal value 2 ton and 3 ton standard weights, standard weights center positioning base/forklift truck and other standard devices and supporting facilities. The standard devices and supporting facilities are common equipment. This measuring method is simple and easy to operate. Corresponding data are convenient for computer processing and statistics. Reference value of the calibration point coordinate is selected as the same with the limit error stipulated in railway freight loading and reinforcement, which can meet the needs of traceability of measurement value of railway special measuring instruments.

Crane limiter is a kind of weighing protection device which prevents the crane from being in danger of overloading operation by detecting the lifting weight. It's also called as crane overload limiter.

The crane limiter is generally composed of two parts: Strain gauge load cell and load cell controller. The load cell is used to measure the lifting weight, while the load cell controller discriminates according to the lifting weight and outputs corresponding state control signal.

The greatest feature of crane limiter is that it effectively combines with the specific structure of lifting machinery, thus ensuring that the use of load cell and load cell controller would not destroy the safety of lifting machinery. Meanwhile, it shall also meet the functional requirements of reliable performance, convenient maintenance and high measurement accuracy.

When the load cell faults occur. Firstly, it's necessary to carefully distinguish the system structure and whether the load cells have the following problems before removing the load cell from the weighing system:

- Check if there is a system transmission failure, the fault may be caused by dust, misalignment of mechanical parts or delayed component force transmission, rather than a load cell fault.

- Check if there are damages, rust or obvious wears at the force transmission part of the system. In winter days, it shall be noticed that whether the force transmission part is frozen, which affects the force transmission and relay of the system.

- Check whether the caging device of the system works and if the gap meets the requirements.

- Check whether the load cell cable is correctly connected to the junction box and display instruments, if there are broken wires or bad contacts between connecting wires. Focus on checking the connection reliability of nine-core plug of the bus and junction box.

- Check if there are faults in connection boxes and meters, particularly the potentiometers and terminals in junction box.

- Check whether the load cell is corroded or damped (particularly the patch hole area). Check the completeness of load cell cable. Check the environment at the entrance of load cell cable.

In order to ensure the load cell accuracy and service life, following details and tips should be paid attention to in the installation of load cell:

- Load cells should be handled lightly and gently. Particularly for the small capacity load cells with alloy aluminum as the elastomer, any impact or drop caused by vibration may cause great output error.

- When designing and installing the loading device, the action line of loading force should coincide with the stress axis of load cell, so as to minimize the effects of inclined and eccentric loads.

- On level adjustment. If a single load cell is used, the mounting plane of its base should be adjusted to horizontal by a gradienter. If several load cells are used for measuring at a same time, the mounting surface of their base should be kept in one horizontal plane, so as to ensure that each load cell bears a basically same force.

Selection of load cells in the weighing system usually considers the capacity, accuracy, installation space of load cells, possible influence of surrounding environment on load cells, loading types and service life of load cells. The weighing system of engineering mixing equipment is no exception, but the only difference is that different weighing systems focus on different aspects due to different requirements and working conditions of engineering mixing equipment.

Several problems need to be considered when selecting the load cell for the weighing system of engineering machinery mixing equipment. This article focused on analyzing the influence of the protective structure of the load cell on the operational reliability of the engineering machinery mixing equipment. It is pointing out that the protection class represented by the IP code cannot cover the full protection requirements of the load cell. Different types of mixing plant are recommended to use the load cells with different protection capabilities.

Engineering mixing equipment include concrete mixing plant, asphalt mixing plant, stabilized soil mixing plant and marine concrete mixing plant, the concrete mixing plant is most commonly used. Next analyses are made with the concrete mixing plant as an example.

S type load cell is widely used for hopper scale and mechanical scale automation renovation. S type load cell has customizable capacity from 5kg, 30kg, 100kg, 500kg, 1000kg, 2 ton to 7 ton.

S type load cell is widely used for hopper scale and mechanical scale automation renovation. S type load cell has customizable capacity from 5kg, 30kg, 100kg, 500kg, 1000kg, 2 ton to 7 ton.

in the company according to the main methods mentioned in this article, and then measure to confirm the calibration results. Based on the calibration results, containers whose eccentric load conforms to the requirements could be loaded. After the detection and confirmation from railway freight car overload and eccentric load detecting device, over-tolerance of eccentric load data is effectively reduced.

in the company according to the main methods mentioned in this article, and then measure to confirm the calibration results. Based on the calibration results, containers whose eccentric load conforms to the requirements could be loaded. After the detection and confirmation from railway freight car overload and eccentric load detecting device, over-tolerance of eccentric load data is effectively reduced.