ATO Load Cells

+1 800-585-1519 (Toll-free)

Home » Load Cell

Tension load cell ATO-S-LCST-TJL-7 is the most common type of load cell for crane, crane limiter, hook scale, all the lifting equipment measurement and tension force monitoring. The installation of the tension load cell is very simple. Just tied the wire ropes to the holes at both ends of tension load cell, and keep the wire rope from falling off or breaking.

Tension load cell has various capacities for choice, from 2 ton, 3 ton, 5 ton, 10 ton, 20 ton, 50 ton to 100 ton. Other capacities are also can be customized.

Tension load cell has various capacities for choice, from 2 ton, 3 ton, 5 ton, 10 ton, 20 ton, 50 ton to 100 ton. Other capacities are also can be customized.

Shear beam load cell is a useful compression load cell for various electronic scales, such as weighbridge, dynamic truck scale, rail weighbridge, etc. Shear beam load cell has a combined indenter for automatic resetting and self-aligning. So customer no need to choose other load cell connections for their weighing system.  It is very easy to install at the site.

It is very easy to install at the site.

Shear beam load cell features:

It is very easy to install at the site.

It is very easy to install at the site.Shear beam load cell features:

- Unlike the cantilever shear beam load cell, a plurality of screws are used to secure the torque balance at the root. Only one screw is required at each end, and the linearity of the load cell can be adjusted.

- The steel ball and the ball seat transmit the load in point contact, and the centering is convenient to install. The steel ball only feels the axial load, and does not transmit the lateral load and the lateral torque, so as to ensure the rapid and accurate reset of the electronic weighing instrument.

Column type load cell is a compression load cell with high capacity. It can be widely used in pharmaceutical and chemical, coal metallurgical industry, and electronic truck scale, rail weighbridge, warehouse scale, hopper scale, etc.

The elastic element of column type load cell can realize integrated design of elastic elements and swing posts. In other words, elastic elements and double spherical swing posts are integrated into one whole structure. Its elastic elements can also help automatically achieve self-alignment and self-spacing of the double-spherical swing post, decrease the loader height and improve stability.

The elastic element of column type load cell can realize integrated design of elastic elements and swing posts. In other words, elastic elements and double spherical swing posts are integrated into one whole structure. Its elastic elements can also help automatically achieve self-alignment and self-spacing of the double-spherical swing post, decrease the loader height and improve stability.

Tension and compression load cell has column type structure and good reliability. It can be used for various scales, such as electronic batching scale, hopper scale and electronic hook scale. Tension and compression load cell has different capacity for customer selection.

For load cell installation, ATO-S-LCS-TJL-4 tension and compression load cell also need load cell connections. There are lifting hooks and lifting rings for tension force measurement. The spherical indenter can be used for compression force measurement.

For load cell installation, ATO-S-LCS-TJL-4 tension and compression load cell also need load cell connections. There are lifting hooks and lifting rings for tension force measurement. The spherical indenter can be used for compression force measurement.

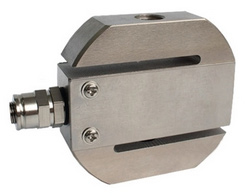

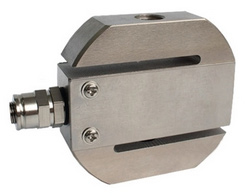

S type load cell is a tension and compression load cell. There are two thread holes just in both ends of strain gauge load cell for mounting.  S type load cell is widely used for hopper scale and mechanical scale automation renovation. S type load cell has customizable capacity from 5kg, 30kg, 100kg, 500kg, 1000kg, 2 ton to 7 ton.

S type load cell is widely used for hopper scale and mechanical scale automation renovation. S type load cell has customizable capacity from 5kg, 30kg, 100kg, 500kg, 1000kg, 2 ton to 7 ton.

S type load cell features:

S type load cell is widely used for hopper scale and mechanical scale automation renovation. S type load cell has customizable capacity from 5kg, 30kg, 100kg, 500kg, 1000kg, 2 ton to 7 ton.

S type load cell is widely used for hopper scale and mechanical scale automation renovation. S type load cell has customizable capacity from 5kg, 30kg, 100kg, 500kg, 1000kg, 2 ton to 7 ton.S type load cell features:

- Simple and compact structure, small size and light weight

- Strong anti-eccentricity and lateral load capacity

- Good Inherent linearity

- Overload protection

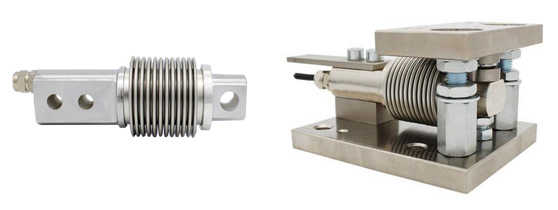

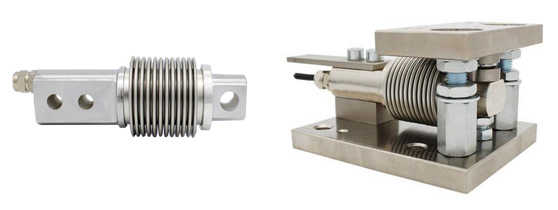

Beam load cell with bellows is a tension and compression load cell. It adopts bellows welding seal structure and cantilever shear beam elastic element. Beam load cell is filled with inert gas to obtain good anti-overload, anti-fatigue and anti-eccentric load capacity. Beam load cells with bellows have capacity range from 10kg, 20kg, 30kg, 50kg, 100kg, 200kg, 300kg, 500kg to 1000kg. Of course, beam oad cell capacity can be customized according to the requirements.

This time we will introduce a small load cell. It is a tension and compression load cell for force measurement, such as automobile braking force detection.

Single point load cell is the most common load cell for weighing scale in the market. In the early 1980s, in order to cope with the contradiction of requirements (small range, large stiffness and high accuracy) of the electronic price computing scale for commercial use, elastic elements adopt the multibeam structure with a low appearance and a small percentage of materials. The Eρ product is small, the yield rate is high, the specific strength is large, the plasticity is good, and the low-temperature performance is good. Meanwhile, there is 2A12 aluminum alloy with a low elasticity modulus with a favorable mechanical processing performance. The small-range load cell with varied structural types, including aluminum alloy parallel beam, central beam, and central ring, have been subsequently developed. Its mechanical characteristic is to generate the bending stress (or normal stress) generated by combination between the upper stress beam and the flexible beam of elastic components. Though the bending stress is used, multiple parallel beams have their mechanical characteristics. Therefore, loading point changes of elastic elements show poor sensitivity towards output. In other words, the structure of bending stress has the structural characteristics of the shear stress. Therefore, it has found wide applications in the electronic price computing scale and the electronic portable platform and bench scale.

In the early 1980s, in order to cope with the contradiction of requirements (small range, large stiffness and high accuracy) of the electronic price computing scale for commercial use, elastic elements adopt the multibeam structure with a low appearance and a small percentage of materials. The Eρ product is small, the yield rate is high, the specific strength is large, the plasticity is good, and the low-temperature performance is good. Meanwhile, there is 2A12 aluminum alloy with a low elasticity modulus with a favorable mechanical processing performance. The small-range load cell with varied structural types, including aluminum alloy parallel beam, central beam, and central ring, have been subsequently developed. Its mechanical characteristic is to generate the bending stress (or normal stress) generated by combination between the upper stress beam and the flexible beam of elastic components. Though the bending stress is used, multiple parallel beams have their mechanical characteristics. Therefore, loading point changes of elastic elements show poor sensitivity towards output. In other words, the structure of bending stress has the structural characteristics of the shear stress. Therefore, it has found wide applications in the electronic price computing scale and the electronic portable platform and bench scale.

In the early 1980s, in order to cope with the contradiction of requirements (small range, large stiffness and high accuracy) of the electronic price computing scale for commercial use, elastic elements adopt the multibeam structure with a low appearance and a small percentage of materials. The Eρ product is small, the yield rate is high, the specific strength is large, the plasticity is good, and the low-temperature performance is good. Meanwhile, there is 2A12 aluminum alloy with a low elasticity modulus with a favorable mechanical processing performance. The small-range load cell with varied structural types, including aluminum alloy parallel beam, central beam, and central ring, have been subsequently developed. Its mechanical characteristic is to generate the bending stress (or normal stress) generated by combination between the upper stress beam and the flexible beam of elastic components. Though the bending stress is used, multiple parallel beams have their mechanical characteristics. Therefore, loading point changes of elastic elements show poor sensitivity towards output. In other words, the structure of bending stress has the structural characteristics of the shear stress. Therefore, it has found wide applications in the electronic price computing scale and the electronic portable platform and bench scale.

In the early 1980s, in order to cope with the contradiction of requirements (small range, large stiffness and high accuracy) of the electronic price computing scale for commercial use, elastic elements adopt the multibeam structure with a low appearance and a small percentage of materials. The Eρ product is small, the yield rate is high, the specific strength is large, the plasticity is good, and the low-temperature performance is good. Meanwhile, there is 2A12 aluminum alloy with a low elasticity modulus with a favorable mechanical processing performance. The small-range load cell with varied structural types, including aluminum alloy parallel beam, central beam, and central ring, have been subsequently developed. Its mechanical characteristic is to generate the bending stress (or normal stress) generated by combination between the upper stress beam and the flexible beam of elastic components. Though the bending stress is used, multiple parallel beams have their mechanical characteristics. Therefore, loading point changes of elastic elements show poor sensitivity towards output. In other words, the structure of bending stress has the structural characteristics of the shear stress. Therefore, it has found wide applications in the electronic price computing scale and the electronic portable platform and bench scale.

The normal stress annular elastic components are mostly the integrated circular structure with the upper and lower double-screw bolts or the integrated annular structure. Under compression load, the elastic annulus and the assembled structure made up of additional pressure head and base wad are usually adopted. It is a tension and compression load cell with capacity from 100kg to 20 ton. If there are special requirements on electronic hook scale, the rectangular annular elements can also be adopted. In order to improve the processing manufacturability, the internal annulus of the rectangular ring can be connected by three connecting holes, including one large central hole and two side holes. The upper and lower loading part of the rectangular elastic elements can be double-screw bolts or pulling ears connected by hinge pins.

Taking the variable belt scale as an example whose full suspension scale rack is supported by four beam load cells, the belt scale divides four load cells into four independent signals which then enter the digital transmitter on site, the digital transmitter converts weighing analog signal into digital signal and convey it to the weighing instrument. By grouping the four independent weighing signals respectively and combining the signal of speed load cell, the weighing instrument would calculate the cumulative and instantaneous flow of three groups of feeding medium, namely one group of main cumulative flow and two groups of auxiliary cumulative flow.

The tubing belt has attracted wide attention for its environmental protection, moisture-proof and high efficiency. At present, there is a new technology that directly conveys the clinker lime powder to the steel plant in a sealed way by tubing belt, it successfully breaks the traditional dynamic measurement method of electronic belt scale, but uses two weighing hoppers to weigh in turn statically, thus achieving the goal of continuous, fast and accurate measurement.

The railway department has traceability requirements for the eccentric load display controllers of container overload and eccentric load detection devices. It calibrates the eccentric load display controllers of container overload and eccentric load detection devices  in the company according to the main methods mentioned in this article, and then measure to confirm the calibration results. Based on the calibration results, containers whose eccentric load conforms to the requirements could be loaded. After the detection and confirmation from railway freight car overload and eccentric load detecting device, over-tolerance of eccentric load data is effectively reduced.

in the company according to the main methods mentioned in this article, and then measure to confirm the calibration results. Based on the calibration results, containers whose eccentric load conforms to the requirements could be loaded. After the detection and confirmation from railway freight car overload and eccentric load detecting device, over-tolerance of eccentric load data is effectively reduced.

The calibration method mentioned in this article is operated with 20 GP container, M12-grade nominal value 2 ton and 3 ton standard weights, standard weights center positioning base/forklift truck and other standard devices and supporting facilities. The standard devices and supporting facilities are common equipment. This measuring method is simple and easy to operate. Corresponding data are convenient for computer processing and statistics. Reference value of the calibration point coordinate is selected as the same with the limit error stipulated in railway freight loading and reinforcement, which can meet the needs of traceability of measurement value of railway special measuring instruments.

in the company according to the main methods mentioned in this article, and then measure to confirm the calibration results. Based on the calibration results, containers whose eccentric load conforms to the requirements could be loaded. After the detection and confirmation from railway freight car overload and eccentric load detecting device, over-tolerance of eccentric load data is effectively reduced.

in the company according to the main methods mentioned in this article, and then measure to confirm the calibration results. Based on the calibration results, containers whose eccentric load conforms to the requirements could be loaded. After the detection and confirmation from railway freight car overload and eccentric load detecting device, over-tolerance of eccentric load data is effectively reduced.The calibration method mentioned in this article is operated with 20 GP container, M12-grade nominal value 2 ton and 3 ton standard weights, standard weights center positioning base/forklift truck and other standard devices and supporting facilities. The standard devices and supporting facilities are common equipment. This measuring method is simple and easy to operate. Corresponding data are convenient for computer processing and statistics. Reference value of the calibration point coordinate is selected as the same with the limit error stipulated in railway freight loading and reinforcement, which can meet the needs of traceability of measurement value of railway special measuring instruments.