ATO Load Cells

+1 800-585-1519 (Toll-free)

Crane limiter is a kind of weighing protection device which prevents the crane from being in danger of overloading operation by detecting the lifting weight. It's also called as crane overload limiter.

The crane limiter is generally composed of two parts: Strain gauge load cell and load cell controller. The load cell is used to measure the lifting weight, while the load cell controller discriminates according to the lifting weight and outputs corresponding state control signal.

The greatest feature of crane limiter is that it effectively combines with the specific structure of lifting machinery, thus ensuring that the use of load cell and load cell controller would not destroy the safety of lifting machinery. Meanwhile, it shall also meet the functional requirements of reliable performance, convenient maintenance and high measurement accuracy.

The crane limiter is generally composed of two parts: Strain gauge load cell and load cell controller. The load cell is used to measure the lifting weight, while the load cell controller discriminates according to the lifting weight and outputs corresponding state control signal.

The greatest feature of crane limiter is that it effectively combines with the specific structure of lifting machinery, thus ensuring that the use of load cell and load cell controller would not destroy the safety of lifting machinery. Meanwhile, it shall also meet the functional requirements of reliable performance, convenient maintenance and high measurement accuracy.

This article is a design of electronic platform scale with double load cells for large tare and small load.

Case of the large tare and small load: The charging bucket weight is about 300kg but the material to be measured is only 15kg, the required accuracy is 0.05%FS under static measurement. According to the actual needs of the production line, the electronic platform scale structure can be used to complete the project.

Case of the large tare and small load: The charging bucket weight is about 300kg but the material to be measured is only 15kg, the required accuracy is 0.05%FS under static measurement. According to the actual needs of the production line, the electronic platform scale structure can be used to complete the project.

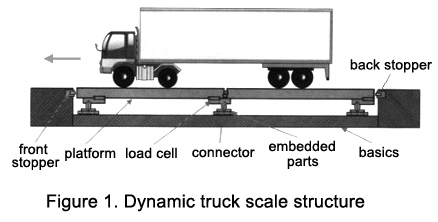

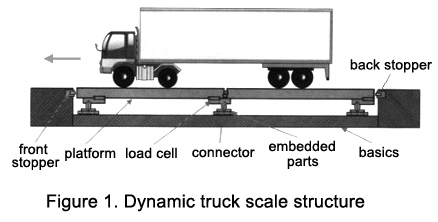

For large truck electronic toll collection (ETC) system, the key technology is weighing, while the key equipment for weighing is dynamic truck scale. Dynamic truck scale is developed from static truck scale, the main load cells it uses are column type load cells and beam load cells. Someone believe that choosing column type load cells can have high response frequency and weighing accuracy, while others think choosing beam load cells can provide stable precision and is easy for installation.

The merits and demerits of column type load cell and beam load cell have been debated endlessly, but how to select the column type load cell and beam load cell? This article will focus on analyzing this problem.

The merits and demerits of column type load cell and beam load cell have been debated endlessly, but how to select the column type load cell and beam load cell? This article will focus on analyzing this problem.

In order to improve competitiveness, it's common for the wharves to provide bulk packaging services now. For small wharves, due to the influence of market supply and demand, the arrival interval of each batch of goods varies, sometimes it's very long, and the packaging equipment keep idle for a long period. Under this background, if the goods are transported to a warehouse for packaging, it not only leads to extremely high cost for equipment transportation, but also results in a low utilization rate of equipment, so it is not reasonable on economic. But if the wharf doesn't provide this service, its competitiveness will be seriously affected. It has been a problem for small wharves about how to improve the utilization rate and work efficiency of packaging equipment and reduce production cost. In order to meet the market requirements of small and medium-sized enterprises with dispersed packaging sites and low utilization of equipment, a small moveable packing machine with three bellows beam load cells forsuspend weighing emerges as the times require. It can be widely used for quantitative packaging of bulk materials in small wharf, grain and oil system, feed processing and other industries.